We offer a diverse range of services that showcase our expertise and commitment to precision craftsmanship. With over 20 years of experience, we excel in delivering innovative solutions across various domains:

Customized stainless steel commercial kitchens offer the perfect solution for businesses requiring a professional, efficient and hygienic kitchen. Built to the exact specifications of the customer, these kitchens incorporate the latest technology and functionality to create a seamless and productive cooking environment. Stainless steel is the ideal material for commercial kitchens as it is durable, easy to clean and resists corrosion. Customized kitchens can include a range of features such as advanced cooking equipment, specialized ventilation systems, ample storage and organization solutions, and ergonomic workspaces. The fully customized design ensures that the kitchen layout meets the needs of the specific business, providing a versatile and flexible space that can be adapted to suit any culinary task. These kitchens are perfect for restaurants, hotels and catering businesses that require a reliable and efficient cooking space that will provide years of service.

Specialized contract manufacturing involves outsourcing manufacturing services to third-party companies that have expertise, equipment, and resources in producing specific goods or products. AMW provide custom manufacturing services for industries such as pharmaceuticals, biotech, medical devices, aerospace, defense, automotive, food, and electronics. The need for specialized contract manufacturing arises when companies lack the in-house facilities, equipment, or expertise required to produce certain products. AMW provide a range of services from design and prototyping to production and assembly. We at AMW offer a level of expertise that is not available in-house, they stay up to date with the latest technology, and they can produce high volumes of products at a lower cost. Utilizing specialized contract manufacturing allows companies to focus on their core competencies and to improve their product offerings.

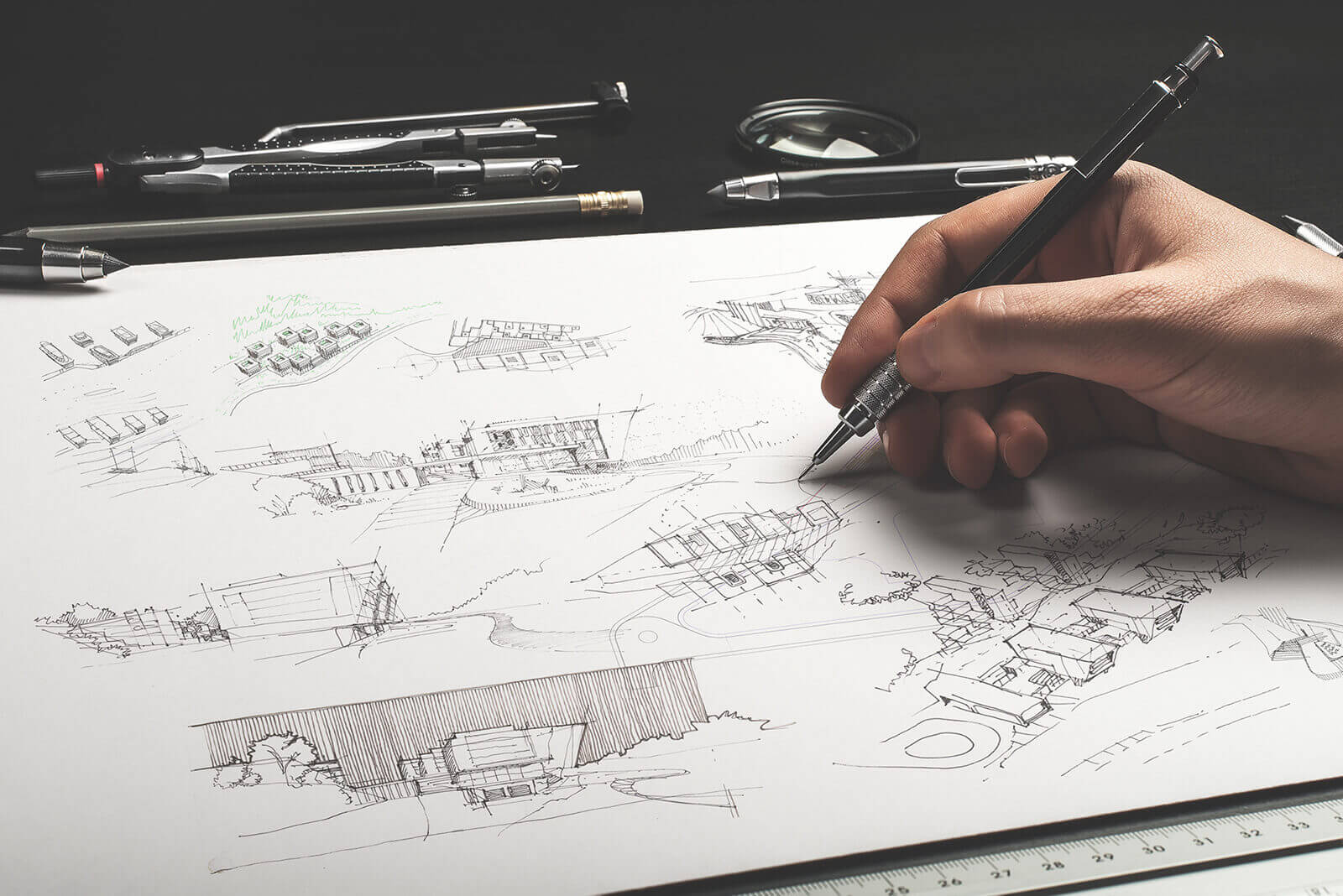

Architectural drawing involves creating detailed technical drawings that show the layout and design of a space, including dimensions, materials, and other specifications. Drafting involves creating precise 2D and 3D renderings of a design. Design involves conceptualizing and creating a plan for a project that meets both the client’s needs and industry standards. Project management involves overseeing the entire process from start to finish, which includes planning, budgeting, scheduling, and coordinating with all relevant stakeholders. In sheet metal fabrication and manufacturing, architects and designers must take into account the properties of the material and how it can be bent, cut, and shaped to meet the desired specifications. Throughout the project, the project manager must ensure that the design is followed correctly and take corrective actions when necessary to ensure that the final product meets the project requirements.

A waterjet cutter is a manufacturing tool that uses a highly pressurized stream of water to cut through a variety of materials, such as metal, glass, stone, and ceramics. An abrasive material, such as garnet, can also be added to the water to increase its cutting power. The waterjet uses high-pressure pumps to push the water and abrasive material through a nozzle that focuses the stream into a precise cutting edge. One of the key benefits of waterjet cutting is its versatility, as it can cut through virtually any material without generating heat, which can lead to warping and other damage. It also allows for complex shapes to be cut with a high level of accuracy, and it can produce very clean cuts with minimal kerf or waste material. Additionally, waterjet cutting is environmentally friendly and produces no hazardous waste materials, making it a sustainable cutting option.

We begin by listening. Understanding your vision, requirements, and expectations is paramount. Our initial consultations involve comprehensive discussions to grasp the essence of your project.

With a clear understanding of your needs, our team of experts translates concepts into tangible designs. Meticulous planning and innovative strategies are employed to bring your vision to life.

Utilizing cutting-edge CNC technology and our skilled workforce, we commence the fabrication phase. Here, precision meets artistry as we craft each component with utmost attention to detail.

Rigorous quality checks are integral to our process. At every stage, we ensure that the highest standards are maintained, guaranteeing a flawless end product.

Our seasoned professionals handle the installation phase with finesse, ensuring seamless integration and meticulous finishing. The project isn’t complete until every detail meets our exacting standards.

Your satisfaction is our priority. We involve you at every crucial stage, seeking your feedback and collaboration to ensure the final result aligns perfectly with your vision.

Even after completion, our commitment doesn’t waver. We offer continued support and assistance to address any queries or maintenance needs, ensuring lasting satisfaction with our work.

Architectural Metalwork is an Australian metalwork company with over 20 years of experience. We have established a reliable reputation for providing quality construction at competitive prices in a timely manner.